Alamar Sanya Gland

Alamar Sanya Gland

LATSA Gland

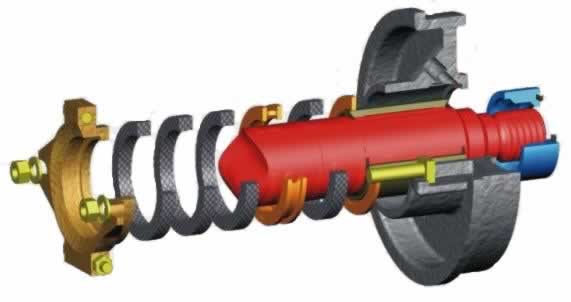

Hannun gland shine daidaitaccen nau'in hatimin da aka karɓa don yawancin aikace-aikacen famfo na slurry saboda ƙarfin ƙarfin dangi, yanayin rashin nasara a hankali da sauƙin kulawa.

MAGANIN HALIN Gland

Alamar gland tana ƙunshe da ɗaki (Stuffing Box) wanda yake ɗauke da kayan aikin hatimi masu tsafta kamar Zobban fitilun Rama, Ryalli na Wuya da Packaukar Gland. Chamberakin yana ba da damar watsa ruwa don ciyarwa a cikin yankin hatimin ta ramin abinci. Wucewa cikin tsakiyar ɗakin shinge ne wanda zai iya kasancewa da hannun riga wanda ya kasance wanda yake jujjuya kayan da yake ajiyewa a cikin dakin sealing ko akwatin sharar. Ana amfani da matsin lamba tsakanin kunshin da hannun shaft ta hanyar mai bin gland wanda idan aka matsa matse kayan, wannan yana samarda layin layin tsakanin hannun riga da kunshin, tsakanin matsin lamba a cikin famfunan da yanayin waje da famfunan.

A dabi'ance wannan gogayyan yana haifar da zafi wanda dalilin hada ruwa shine ayi abinda yake fada, tozartar kuma sanyaya layin hatimi tsakanin bangarorin da suke tsaye da juyawa. A cikin famfunan slurry wanda zai iya yin famfo ba kawai samfuran da aka yi wa larura ba har ma da acidic ko alkaline mafita alawus ana bukatar a yi don rage ba kawai illar gogayya tsakanin hannun riga da shiryawa ba har ma da lalata da lalatawa.

RASHIN HANYAR HALIN Gland

Akwai manyan nau'ikan nau'ikan 3 na kai hari akan hatimin gland a cikin famfunan slurry wanda ke haifar da gazawar hatimi. Waɗannan na iya zama ɗayan mutum ko haɗakar sakamako.

1. Lalata - Gabaɗaya ana haifar dashi ne ta hanyar ruwan gishiri ko yanayin sinadarai tare da zaɓin kayan da ba daidai ba. Baya ga sinadarai kai tsaye ko tasirin abu akan abu mai kyau game da kirdadon abubuwa a saman rufaffen hatimi na iya haifar da gazawar ta sassan yashewa.

2. Yashewa / Wear - Yawanci ana haifar da shi ne sakamakon gurɓatarwar dakin sealing ta hanyar yin slurry ana turawa ta hanyar rashin kwararar ruwa da kuma matsi na ruwan sealing, kuma ana iya haifar dashi ta hanyar ƙarar ruwa ko kuma ta hanyar amfani da karfi fiye da kima tsakanin takunkumin sel ta hanyar matse mai bin gland .

3. Gogayya - A yadda aka saba ana samu ta hanyar daidaita ƙyamar gland don cimma kusan zuban ruwa. Koyaya wannan wannan yana haifar da raunin aikin ruwan sha a sanyaya gland. Dukkanin pamfunan da aka hatimce an tsara su ne don zubewa kuma ya kamata a bar su a hankali ko kuma hanzarin diga na kwararar ruwa daga garesu don saukaka sanyaya da flushing ko layin hatimi.

Rashin sakewar zagaye na hatimin gland shine yake cigaba gaba sabili da ƙarfin ƙirar wanda yake da mawuyacin hali, gazawar hatimin gland yana da wuya da sauri. Makamashi shine ainihin tushen gazawa, kimiyyar lissafi tana gaya mana cewa makamashi yana bin hanyar mafi ƙarancin juriya. A cikin wata glandar da aka danneta saboda duk wani hadewar yanayin da ke sama ana canzawa da yaduwa a duk sassan sakonnin, wannan makamashin na iya kasancewa ta hanyar sinadarai, mai yuwuwa, motsa jiki da sauransu hade da ko dai ruwaye ko kuma masu karfi a cikin dakin . Don haka a zahiri ruwaye / daskararru zasu nemi saki ko canza makamashinsu zuwa ga mafi raunin bangaren a cikin dakin kasancewar shiryawa. Wannan shine ainihin abin da aka tsara hatimin gland, yi shi ne babban abin sadaukarwa a cikin ɗakin kuma saboda haka ana canza shi sau da yawa fiye da sauran abubuwan.

Koyaya an haɓaka kayan aiki na gland na lokaci zuwa ma'anar cewa abubuwa na musamman kamar su Kevlar, Carbon Fibers da Teflon an haɗa su cikin ƙirar ta, wannan ya haifar da shiryawa yana da natsuwa kuma yana iya yin tsayayya da lalacewa ko rarraba makamashi zuwa wani yankunan ɗakin hatimin, wato ɓangaren hadaya na biyu kasancewar ƙafafun shaft.

Hannun hannayen riga tare da lantern da zobban wuya sune watakila na biyu da aka canza mafi yawancin kayan haɗin tsarin gland. an sanya hannayen riga na tarihi daga abubuwan girar da ke da wahalar sakawa fiye da kayan aikin gland don su dade. Amma kamar yadda shiryawa ya samo asali cikin ƙarfi da zane tare da haifar da dogon hannayen hannayen hannayensu ko dai an canza su tare da zagayowar shiryawa ko haɓaka ta hanyar sabbin kayan aiki, tsarin shafawa ko haɗuwa duka biyun. Ingantattun hannayen riga wanda ke ba da kwalliya mai wuya don juriya sa'annan zai iya ɗaukar sabbin kayan aiki tare da ba da ingantaccen rayuwa a duk hanyar layin. Kodayake tsarin sutura da yawa suna da nakasu da raunin tsarinsu wanda idan ba a tallafawa da wadataccen abinci na kwararar ruwa da sanyaya ruwa na iya haifar da haɓakar haɓakar glandon.

Don ƙarin bayani game da gazawar hannayen riga mai rufi don Allah koma zuwa Shafin Hannun CIS.

RASHIN YADDA AKA KASHE

Matakan da za a rage illolin yanayin gazawar hatimin gland sun haɗa da.

1. Kanfigareshin Sealing - Tabbatar da cewa kun zaɓi madaidaicin tsarin buga hatimi don aiki da yanayin aiwatarwa. A kan wannan akwai samfuran bayan kasuwa da yawa waɗanda ke ba da haɓaka don buga hatimi a kan ƙirar asali, kowane miƙa yana buƙatar a kimanta shi a kan da'awarta da cancantar la'akari ba kawai aikin famfo ba amma yanayin aiwatarwa.

2. Ruwan Ruwa - Tabbatar cewa gland yana da madaidaitan tsari na sassa tare da wadataccen ruwan sha mai kyau a matsewar dama da kwarara. Fiye da 90% na matsalolin sealing za'a iya gano su zuwa rashin isasshen abinci na tsaftataccen ruwan sha a madaidaicin matsin lamba, tare da daidaitaccen gland.

3. Zaɓin Kayan aiki - Zaɓin abubuwan da suka dace don dacewa da yanayin aikin famfo da kuma samun ruwan fanko.

Boxing Stuffing - A cikin aikin sunadarai ana buƙatar amfani da abu mara ƙarfi duk da haka mafi yawan kayan aiki na sinadarai basu da wuyar sakawa saboda haka ana iya zaɓar wani abu mai sulhu wanda zai ba da daidaito na rayuwar lalacewa da juriya ta sinadarai. Don sanya kayan aiki mai wahala ana iya amfani da kayan aiki amma kuna buƙatar tuna cewa ƙaramar kayan sannan gabaɗaya ƙananan ƙarfin ƙarfin inji ne da ƙarfin matsi mai zuwa. Don kayan aikin Chemical da kayan aiki masu wuya kuna buƙatar kayan abu wanda yake da lalacewa kuma yana da tsayayyar sinadarai. Don wannan yanayin Slurrytech sun haɓaka SB-WRC (Akwatin Akwatin - Wear Resistant Carbide face), an gina wannan hatimin ne daga akwatin Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Wuta ɗakin

Shaft Hannun Riga - Hannun hannayen hannu suna juyawa tare da maɓallin famfo a kan zobba marasa aiki na shiryawa a cikin akwatin sharar. Matsakaicin kayan aji na hannayen riga suna da taurin ƙarfe kuma gabaɗaya suna da ƙarfi sosai, fanfunan da ke aiki da waɗannan hannayen riga yawanci gazawar sannu a hankali na taron hatimi. Akwai sabbin hannayen riga tare da nau'ikan kayan kwalliya masu tauri da aikace-aikacen aikace-aikace don waɗannan. Yawancin hannayen riga masu rufi suna fama da rarrabuwa daga kayan kaddarorin tsakanin matattarar abu da rufin wanda zai haifar da saurin gazawar hatimin gland. An tsara hannayen riga na slurrytech CIS don bayar da danshi mai matukar wahala wanda aka sanya shi a cikin matattarar don kauce wa halaye na gargajiya na galibin tsarin sutura. Da fatan za a duba shafi na CIS Sleeve. don ƙarin bayani akan hannayenmu.

Kayan Gland - Gland ɗin zamani na yau yana zuwa da yawa iri, kunsa da kayan haɗi fiye da yadda ake samu a da. babbar doka tare da shiryawa shine don tabbatar da cewa kun dace da kunshin don sinadarai, lalacewa da kayan glandon da ake amfani da su da kuma la'akari da kasancewar ruwan gland da matsi. Duk waɗannan abubuwan suna tasiri yadda ba kawai ɗaukar kaya kawai ba amma hannun riga da sauran abubuwan haɗin zasu riƙe a cikin yanayin aiki. Abin baƙin cikin shine babu wani nau'in da ya dace da duk yanayin ƙirar kayan aiki.

A Slurrytech sun tsara namu janar na kayan kwalliya wanda ya kunshi Kevlar sasanninta don karfi, katangar Teflon da aka zana don rage tashin hankali da kuma ginshiƙan ginshiƙi mai mahimmanci don shafawa da daskararru.

Duk gland a cikin yanayin slurry zasu sha wahala daga daskararrun abubuwa a kan lokaci, mun tsara kayanmu tare da wannan a hankali don ya sami damar ɗaukar sama da sha abubuwan gurɓatawa maimakon ɗaure su tsakanin rigar da kayan. Matsayinmu na shirya abubuwa yana aiki daidai yadda yakamata don gami ko hannayen riguna masu rufin yumbu kuma ya dace da ɗakunan matakan pH da matsi iri-iri.

Winclan ma'aikata

Muna jin daɗin ƙarfin fasaha, kayan aiki masu kyau da kayan aikin dubawa, don haka zamu iya samar muku da samfuran inganci masu tsada.

Game da mu/ Ka'idarmu tana da inganci, a lokacin jigilar kaya, farashi mai sauƙi.

- Turanci

- Faransanci

- Bajamushe

- Fotigal

- Sifeniyanci

- Rashanci

- Jafananci

- Yaren Koriya

- Larabci

- Irish

- Girkanci

- Baturke

- Italiyanci

- Danish

- Romaniyanci

- Indonesiyanci

- Czech

- Afrikaans

- Yaren mutanen Sweden

- Yaren mutanen Poland

- Basque

- Katalaniyanci

- Esperanto

- Hindi

- Lao

- Albaniyanci

- Amharic

- Armeniyanci

- Azerbaijani

- Belarusiyanci

- Bengali

- Bosniyanci

- Bulgaria

- Cebuano

- Chichewa

- Corsikan

- Kuroshiyan

- Yaren mutanen Holland

- Estoniyanci

- Filipino

- Yaren mutanen Finland

- Frisiyanci

- Galiziya

- Jojiyanci

- Gujarati

- Haiti

- Hausa

- Harshen Hawaii

- Ibrananci

- Hmong

- Harshen Hungary

- Icelandic

- Igbo

- Javanisanci

- Kannada

- Kazakh

- Khmer

- Kurdawa

- Kirgiziya

- Latin

- Latvia

- Lituweniyanci

- Luxembou ..

- Macedonia

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongoliyanci

- Burma

- Nepali

- Yaren mutanen Norway

- Pashto

- Farisanci

- Harshen Punjabi

- Sabiyanci

- Sesotho

- Sinhala

- Slovakiya

- Slobaniyanci

- Somali

- Samoan

- 'Yan Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Yukreniyanci

- Urdu

- Uzbek

- Vietnam

- Welsh

- Xhosa

- Yardawa

- Yarbawa

- Zulu